不锈钢矩鞍环填料标准确保工业密封性能的关键规范

不锈钢矩鞍环填料标准:确保工业密封性能的关键规范

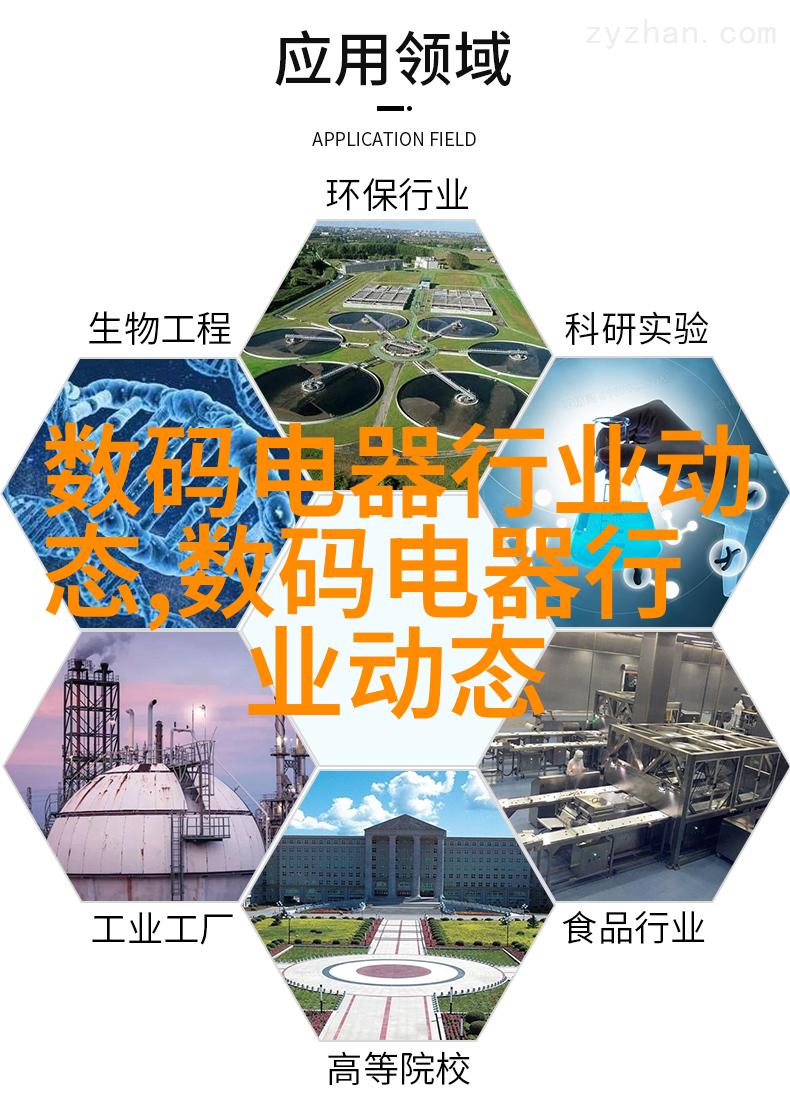

不锈钢矩鞍环填料标准的制定是为了确保在高温、高压和腐蚀性环境下的工业密封性能。这种环形结构使得它能够承受极端条件下的工作负荷,而不锈钢材质则提供了良好的耐腐蚀性。

不锈钢矩鞍环填料标准的背景与重要性

不锈钢矩鞍-ring seals in high-temperature and high-pressure environments, corrosion-resistant materials provide a reliable seal for industrial equipment.

不锈steel material selection criteria

The selection of not only the type of stainless steel but also its specific grade is crucial to ensure the desired level of corrosion resistance and mechanical strength.

Different grades have different levels of chromium content which directly affects the material's ability to resist oxidation and scaling.

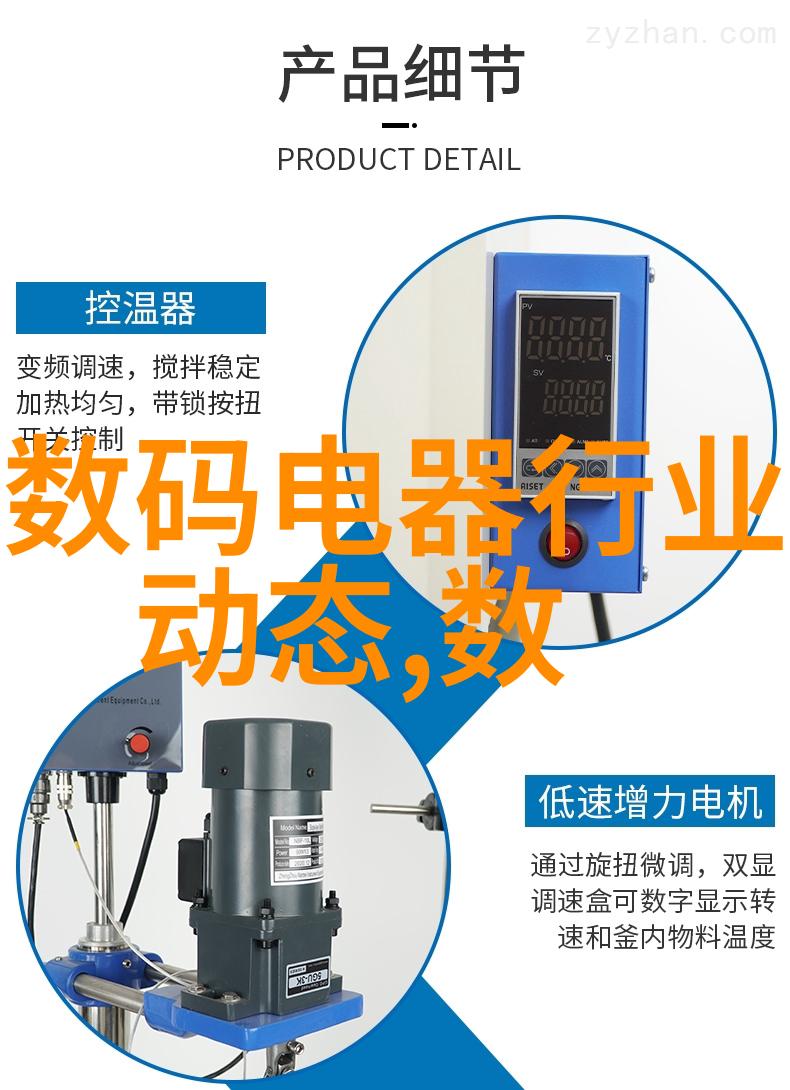

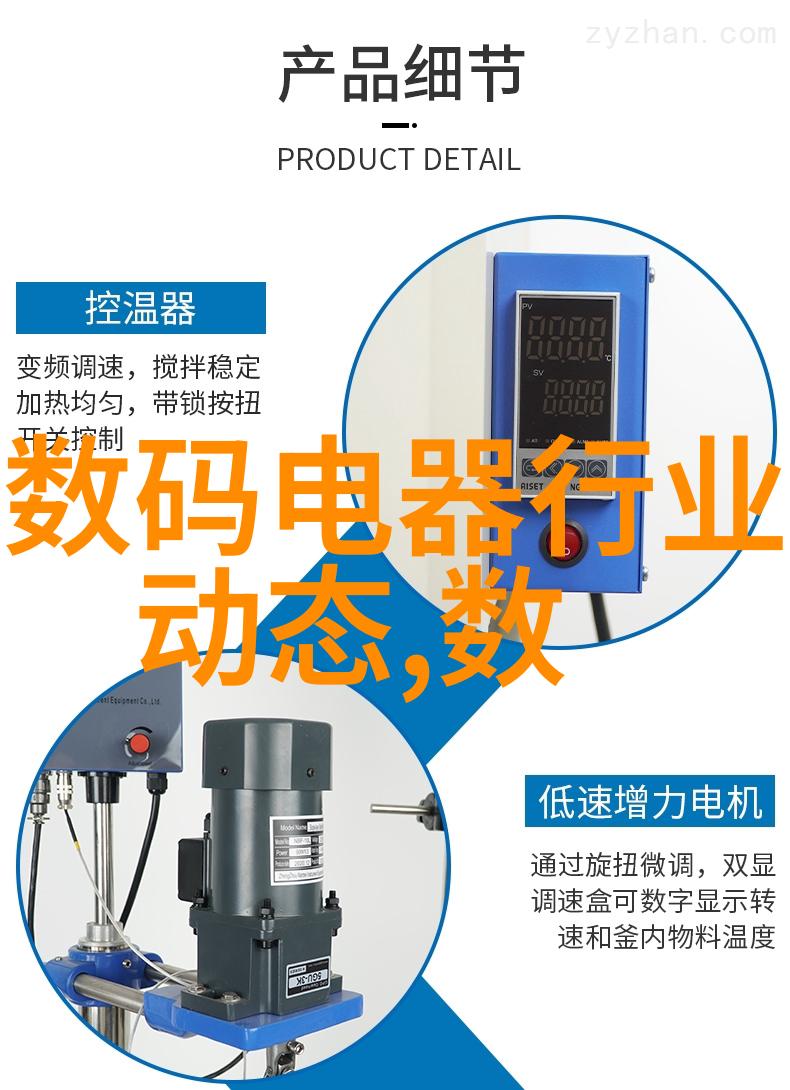

Matrix design considerations

The matrix design should be carefully considered to optimize performance under various operating conditions. Factors such as temperature, pressure, fluid compatibility, and size must be taken into account.

A well-designed matrix will provide a consistent seal across the entire range of expected operating conditions.

Seal face geometry and surface finish requirements

The seal face geometry plays a critical role in determining the overall sealing performance. The surface finish must meet strict standards to ensure minimal leakage.

A smooth surface with precise tolerances ensures that there are no areas where fluid can escape or penetrate through microscopic imperfections.

Installation, maintenance & inspection procedures

Proper installation procedures are vital to achieve optimal sealing performance from day one.

Regular inspections should be performed at predetermined intervals or based on usage patterns to detect any signs of wear or damage before they become major issues.

Compliance with industry standards & regulations

Not only does compliance with industry standards guarantee safety but it also provides assurance that your equipment meets all regulatory requirements.

This includes adherence to ASME B16 series specifications for piping flanges and fittings as well as other relevant codes governing mechanical devices in industries like aerospace or chemical processing plants