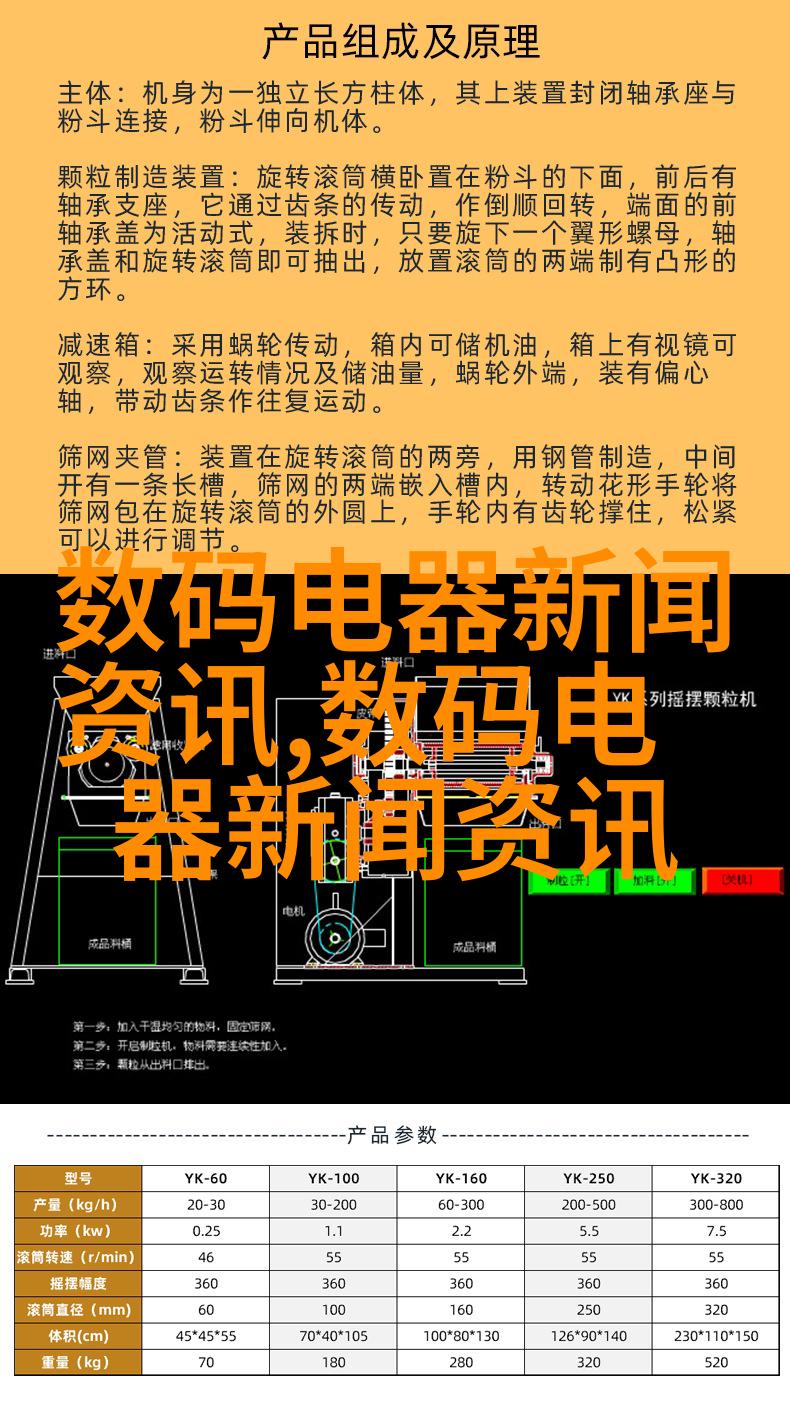

大型纯净水生产线设备系统解析

设备概述

大型纯净水生产线设备是指用于规模化生产高品质纯净水的工业级设备。这些设备通常由多个部分组成,包括源头水处理、过滤、反渗透(RO)、紫外光消毒等关键环节。它们能够从各种原始水源中提取出清洁无菌的饮用水,为家庭和企业提供稳定的供给。

水源选择与预处理

首先,大型纯净水生产线需要确保原材料——即来源于河流、湖泊或地下深层—are free from contaminants and pollutants, such as heavy metals, bacteria, viruses and other impurities. To achieve this goal, pre-treatment processes are implemented to remove coarse particles and large contaminants from the raw water. This includes physical methods like sedimentation tanks or screens that filter out larger debris.

过滤与除垢技术

Next in line is the filtration process which utilizes a series of filters with decreasing pore sizes to capture smaller impurities down to microscopic levels. Activated carbon filtration also plays a crucial role here as it removes organic compounds and improves taste by neutralizing unpleasant odors or flavors.

反渗透技术应用

After passing through the filtration stage, reverse osmosis (RO) technology takes over to further purify water at its molecular level by forcing it through semi-permeable membranes that allow only water molecules to pass through while rejecting dissolved solids and other impurities.

终端处理与包装

The final step involves post-treatment processes such as remineralization (adding back essential minerals), UV disinfection for pathogen elimination, pH adjustment for optimal drinking quality standards before packaging into bottles or containers ready for distribution.

系统自动控制与维护管理

For efficient operation of these complex systems, modern control technologies are employed including automation software that ensures monitoring of all key parameters throughout production runs; alerting operators if any issues arise during processing so prompt action can be taken before affecting product quality; Moreover routine maintenance schedules are set up based on manufacturer guidelines along with periodic inspections performed by qualified technicians ensuring maximum uptime performance across entire facility operations.

安全性考量及合规性要求

Safety considerations play an important part in designing large-scale pure water manufacturing lines where stringent safety protocols must be observed due to potential hazards associated with chemicals used during treatment stages (e.g., chlorine). Additionally compliance with regional health regulations—such as NSF International Standards—and environmental protection laws is strictly enforced since producing clean drinking water directly impacts public health wellbeing while minimizing ecological footprint remains vital responsibility within industry sector today's world context wherein resources scarcity has become increasingly pressing concern alongside growing awareness towards sustainable practices among consumers worldwide hence manufacturers strive hard incorporate green elements wherever possible without compromising on end product quality making sure we provide reliable access fresh potable H2O supplies communities everywhere thus fostering long-term trustworthiness reputation among customers their loyal patrons alike ultimately contributing positively society overall well-being future generations benefitting most significantly this endeavor continues evolve innovate ways ensure highest standards purity transparency sustainability remain paramount objectives guiding development strategies executed within realm industrial pure-water production industry